- semi-trailers in light alloy and steel for tipping bodies ;

- chassis for tanks and isothermal vans ;

- bulk tanks for transportation of animal feed and pulverized materials

EVEN LIGHTER

The whole range of products offer Menci’s reliability, safety and design applied to a line of chassises designed to be equipped with bulk feed tanks for any kind of transport. Manufactured in both steel and light aluminium alloy, the new chassises are designed with bolted structural details, in order to increase the maximum diversification of the range and to facilitate their equipping with bulk feed tanks.

RESONANCE… BODIES

The success of this product echoes back in all markets : strong but lightweight the new steel tipping bodies challenge the competitors, allowing a considerable reduction of the tares. Once again Menci realizes and works out the needs of transports and new road regulations. The sizes of tipping bodies range from 24 sqm to 68 sqm.Also in square tipping bodies the production process has reached highest quality levels.

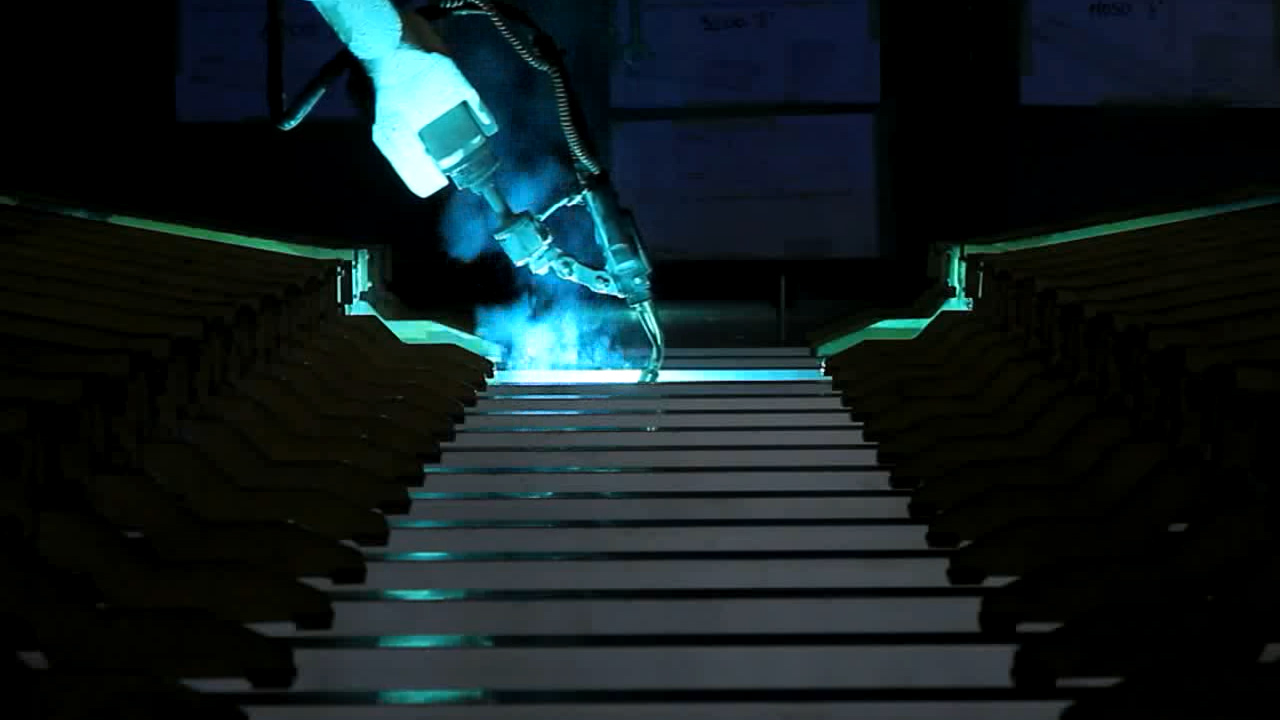

Thanks to the new fully automated welding robots Menci obtains perfect semi-finished products, ready for the final body assembly.

(Watertight walls are provided upon request to increase the possibilities of different kinds of transportation).

NEW TANK FOR TRANSPORTATION AND DELIVERY OF FODDER FOR ANIMAL FEED

The added value of the new tank for transportation and delivery of animal feed is the possibility to transport different products without causing contamination among them, and also the self-cleaning of the tank which allows considerable saving of time and money.

A single transport with different products.

With this new product the company faces even the farthest areas in the foreign markets, strengthening meanwhile its domestic leadership with 150 units sold per year.

A single transport with different products.

With this new product the company faces even the farthest areas in the foreign markets, strengthening meanwhile its domestic leadership with 150 units sold per year.

- New casing with patented modular structure, obtained using extruded sections which allow the application of automated and / or robotic processing technologies: this means therefore a faster preparation and the possibility to assemble the semi-finished products even in farther market areas (with obvious savings in transport/import).

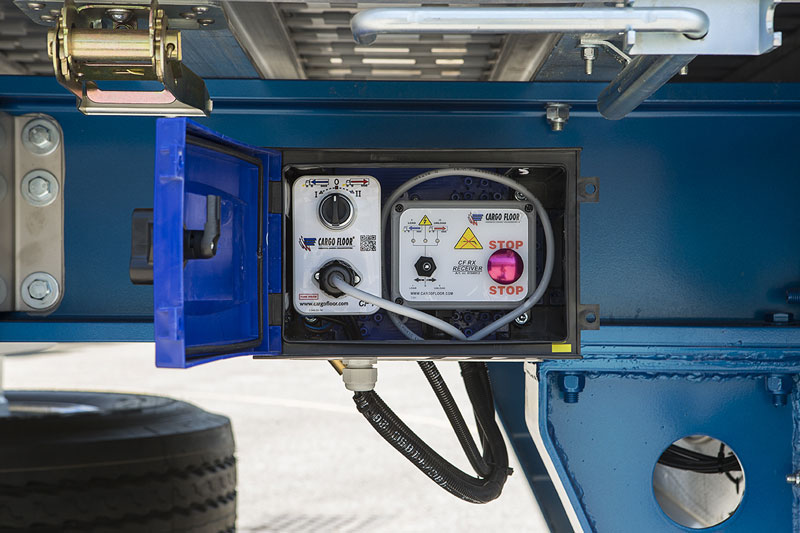

- New patented control system for opening and closing compartments, where all hydraulic components are external to the areas with the feed going through.

- Elimination of all leverage internal to the compartment and of all the parts protruding inside (angles of welding, screw heads, etc.) to avoid any stagnation of the products and thus any phenomenon of fermentation and pollution of the feed.

- Innovative extruded gates which guarantee a perfect seal, avoiding contamination of different foods.

- Longitudinal and transverse polymer augers in direct contact with the new extruded sections for a complete extraction.